Eco Friendly Parcel Packaging - Manufacturers, Factory, Suppliers from China

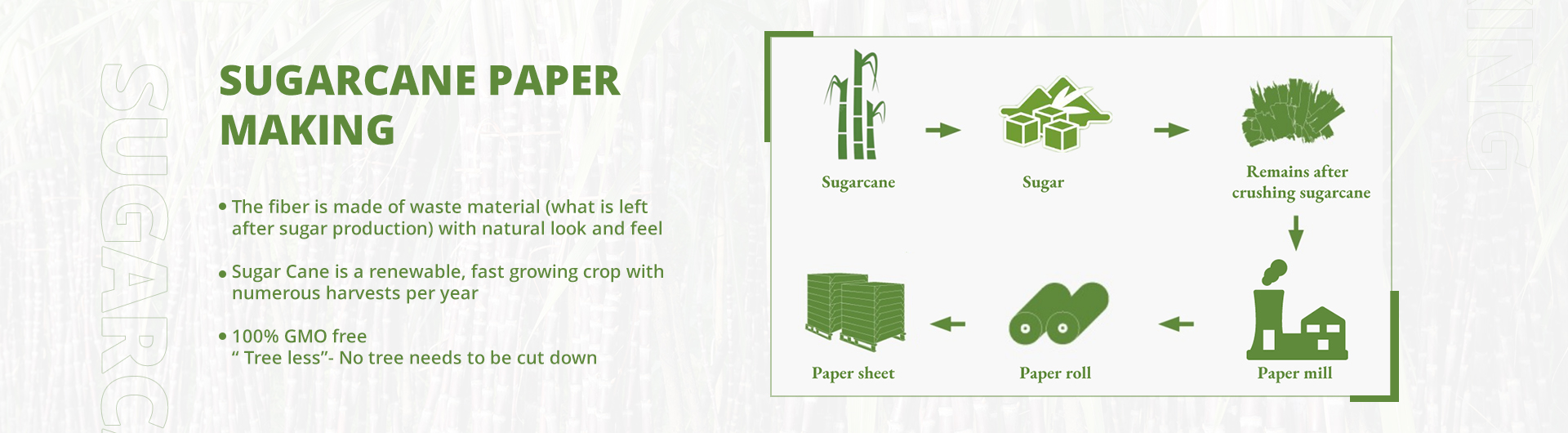

In recent years, the global consumption of paper and paperboard has been on a continuous growth trend. According to the figures for 2022, the total amount of paper and paperboard consumed globally is approximately 417 million tons. However, with an average of about 17 trees needed to produce one ton of paper, that's about 70.8 billion trees that will be cut down each year to make paper and paperboard. This statistic brings us to the alarming fact that a large number of trees are being cut down, which could further exacerbate the effects of global warming. Eco Friendly Parcel Packaging, Eco Friendly Resealable Packaging , Eco Friendly Art Print Packaging , Eco Shipping Packaging ,Singel Wall Paper . In addition, we can also choose tree-free and plastic-free packaging. Sugar cane pulp paper and cardboard, for example, is a sustainable alternative. The sugarcane production process produces by-products, and these leftover fibrous materials can be reused to make pulp. Typically, these by-products are incinerated, causing air pollution and the production of greenhouse gases. However, a company called Nanguo Paper has given these by-products a second life by upcycling them into tree-free paper and cardboard. The product will supply to all over the world, such as Europe, America, Australia,Mombasa, United States,South Africa, Palestine.From the based paper to the packaging of paper cups, mainly through the following processes: 1, PE film: that is, the based paper (white paper) with a film machine with PE film, film one side of the paper is called single-sided PE film paper: both sides of the film is called double-sided PE film paper.2、Slitting:Use the slitting machine to slit the coated paper into rectangular pieces (for the wall of the cup) and (for the bottom of the cup) rolls of simple paper.3, printing: letterpress printing machine in the rectangular sheet of paper with a variety of designs4, die-cutting: with a flat creasing and cutting machine (commonly known as die-cutting machine) will be printed on the graphics of the paper into a fan-shaped piece of paper cups used for cutting5, molding: only need the operator will fan-shaped paper cups and cup bottom rolls of paper to the paper cup molding machine feeding mouth, paper cup molding machine automatic paper feeding, sealing, punching the bottom of the operation can be automatically molded into a variety of sizes you need.The paper cup molding machine automatically feeds the paper, seals the paper, punches the bottom and so on, and then automatically molds the paper cups of various specifications you need. The whole process can be easily operated by one person.6、Packaging:the good paper cups sealed in plastic bags, and then packaged into cartons.

Related Products