Packaging Ecologic - Manufacturers, Factory, Suppliers from China

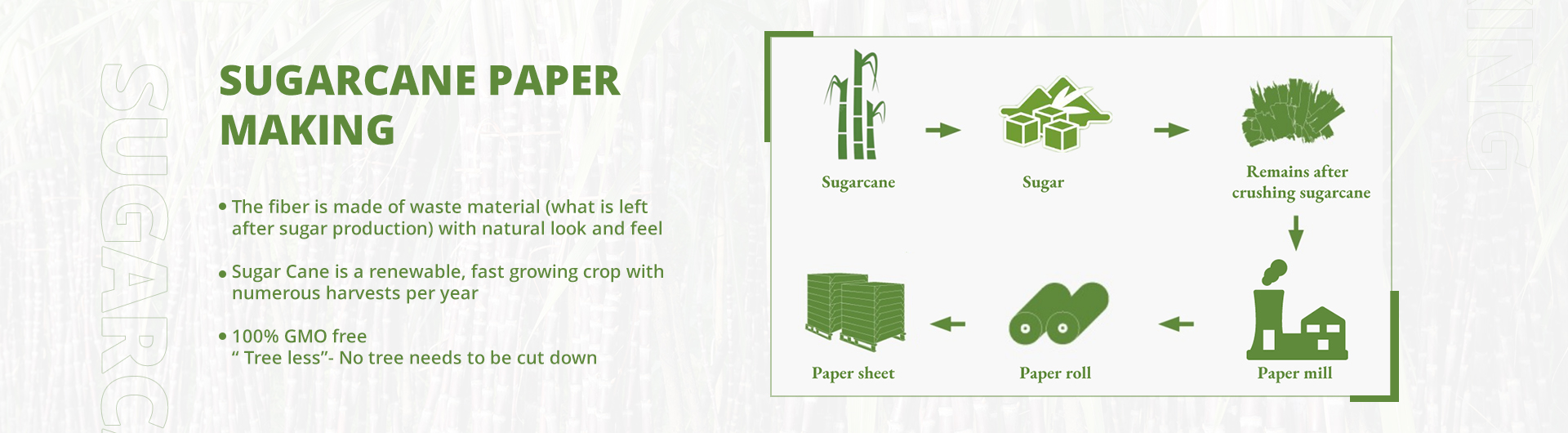

As environmental awareness grows, more and more people are paying attention to the environmental considerations of paper. Cane pulp paper as a sustainable paper material not only uses resources more efficiently in the production process, but also effectively reduces carbon dioxide emissions. This paper discusses why cane pulp paper is a more environmentally friendly paper option and explains why the use of cane pulp paper can reduce CO2 emissions. Packaging Ecologic, Sustainable Paper , Eco Friendly Sushi Packaging , Eco Friendly Packaging Solutions ,Eco Friendly Sushi Packaging . several aspects why sugarcane pulp paper is more environmentally friendly than wood pulp and bamboo pulp paper, and recommend the use of sugarcane pulp paper. The product will supply to all over the world, such as Europe, America, Australia,Brunei, Mombasa,Singapore, Islamabad.Green packaging, also known as pollution-free packaging or environmentally friendly packaging, refers to packaging materials that are harmless to the ecological environment and human health, and are reusable, renewable and sustainable. The concept of green packaging is reflected in two aspects: protecting the environment and saving resources. The two are complementary and inseparable. Among them, protecting the environment is the core, and saving resources is closely related to protecting the environment, because saving resources can reduce the generation of waste, which actually protects the environment from the source. From a technical point of view, green packaging is an environmentally friendly packaging material made from natural plants. It is harmless to the ecological environment and human health, and is conducive to recycling, easy to degrade, and sustainable development. This means that the entire life cycle of green packaging, from raw material selection, product manufacturing to use and disposal, must comply with ecological and environmental protection requirements. To achieve green packaging, we need to start from three aspects: green packaging materials, packaging design and vigorously developing the green packaging industry. For example, paper made from bagasse meets environmental requirements. Bagasse paper can also meet the requirements that packaging on the market needs to meet. Bagasse paper can be widely used in sustainable packaging industry, printing industry and office supplies industry. For example, using sugarcane bagasse paper for food packaging can not only ensure food safety and hygiene, but also reduce the negative impact on the environment. In the printing industry, using bagasse paper to produce books, magazines and other products not only brings a good reading experience, but also reduces dependence on forest resources. In addition, the office supplies industry can also use sugarcane pulp paper to make paper, such as notebooks, letters, and envelopes, thus contributing to a green office environment. In short, green packaging is a packaging method with the core concept of protecting the environment and saving resources. It requires the use of packaging materials made of natural plant raw materials to achieve sustainable development by complying with ecological and environmental protection requirements. In practice, green packaging materials such as bagasse paper have a wide range of applications and can provide environmentally friendly choices for the sustainable packaging industry, printing industry, office supplies industry, etc., and make positive contributions to building a green society.

Related Products