Packaging Paper - Manufacturers, Factory, Suppliers from China

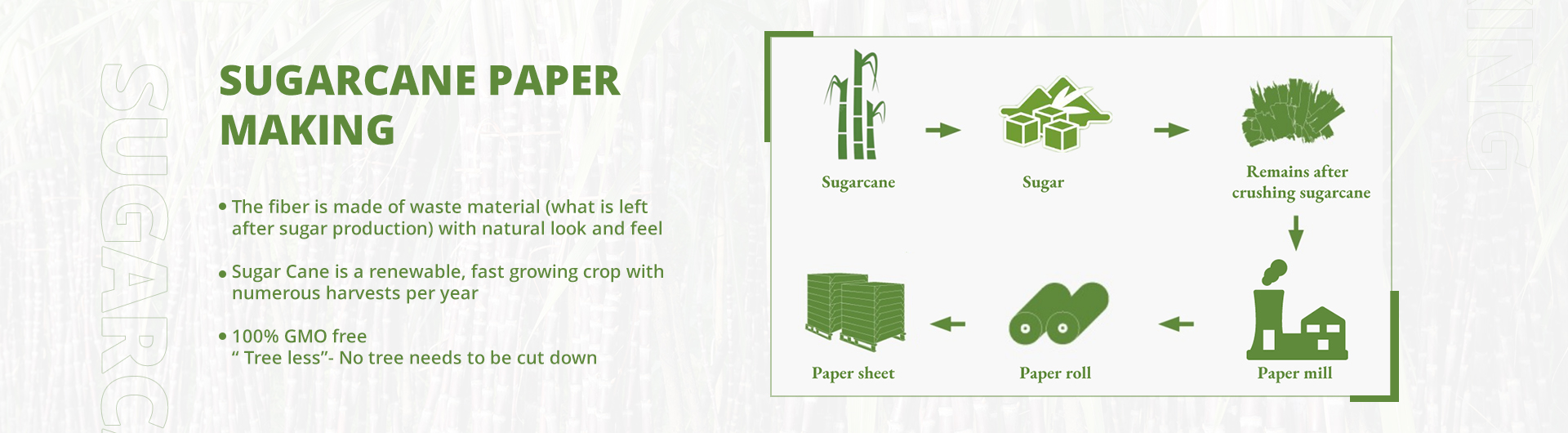

In addition to reducing damage to forests and providing a wide range of uses, paper made from bagasse has other advantages. Firstly, bagasse paper has good quality and printability and can fulfill a wide range of printing and packaging requirements. Secondly, bagasse paper has a low cost, which is an important consideration for companies. In addition, bagasse paper also reduces the negative impact on the environment as it is relatively simple to manufacture and does not require large amounts of energy and chemicals. Packaging Paper, Ocean Friendly Packaging , Eco Friendly Dessert Packaging , Sustainable Meat Packaging ,Eco Friendly Takeaway Containers . Another commonly used material is kraft paper, known for its high breakage resistance and toughness. Kraft paper is one of the more used paper bag materials in the market. Recently, Southland Paper has introduced a kraft paper made primarily from bagasse. This new material also has high tensile strength and toughness and is the best choice for sustainable packaging. Compared to packaging materials such as plastic bags, paper bags are made from natural materials, which are renewable.In the current social atmosphere of increasing attention to environmental protection, the use of sustainable packaging materials can enhance the environmental image of enterprises.As a representative of green packaging materials, the use of paper bags can not only meet the needs of people's lives, but also effectively publicize the enterprise's environmental protection concept, improve the enterprise's social image and brand value. As people's awareness of environmental protection increases, more and more companies are beginning to advocate the use of sustainable packaging materials, and paper bags are the best embodiment of this concept. Through the use of paper bags, enterprises can demonstrate their sense of environmental responsibility and win the recognition and trust of consumers. At the same time, the use of paper bags can also stimulate the environmental awareness of consumers, prompting them to pay more attention to environmental protection, forming a good environmental cycle. The product will supply to all over the world, such as Europe, America, Australia,kazakhstan, Mombasa,Libya, Buenos Aires.From the based paper to the packaging of paper cups, mainly through the following processes: 1, PE film: that is, the based paper (white paper) with a film machine with PE film, film one side of the paper is called single-sided PE film paper: both sides of the film is called double-sided PE film paper.2、Slitting:Use the slitting machine to slit the coated paper into rectangular pieces (for the wall of the cup) and (for the bottom of the cup) rolls of simple paper.3, printing: letterpress printing machine in the rectangular sheet of paper with a variety of designs4, die-cutting: with a flat creasing and cutting machine (commonly known as die-cutting machine) will be printed on the graphics of the paper into a fan-shaped piece of paper cups used for cutting5, molding: only need the operator will fan-shaped paper cups and cup bottom rolls of paper to the paper cup molding machine feeding mouth, paper cup molding machine automatic paper feeding, sealing, punching the bottom of the operation can be automatically molded into a variety of sizes you need.The paper cup molding machine automatically feeds the paper, seals the paper, punches the bottom and so on, and then automatically molds the paper cups of various specifications you need. The whole process can be easily operated by one person.6、Packaging:the good paper cups sealed in plastic bags, and then packaged into cartons.

Related Products