PE Coated Paper Bowl Fan - China Factory, Suppliers, Manufacturers

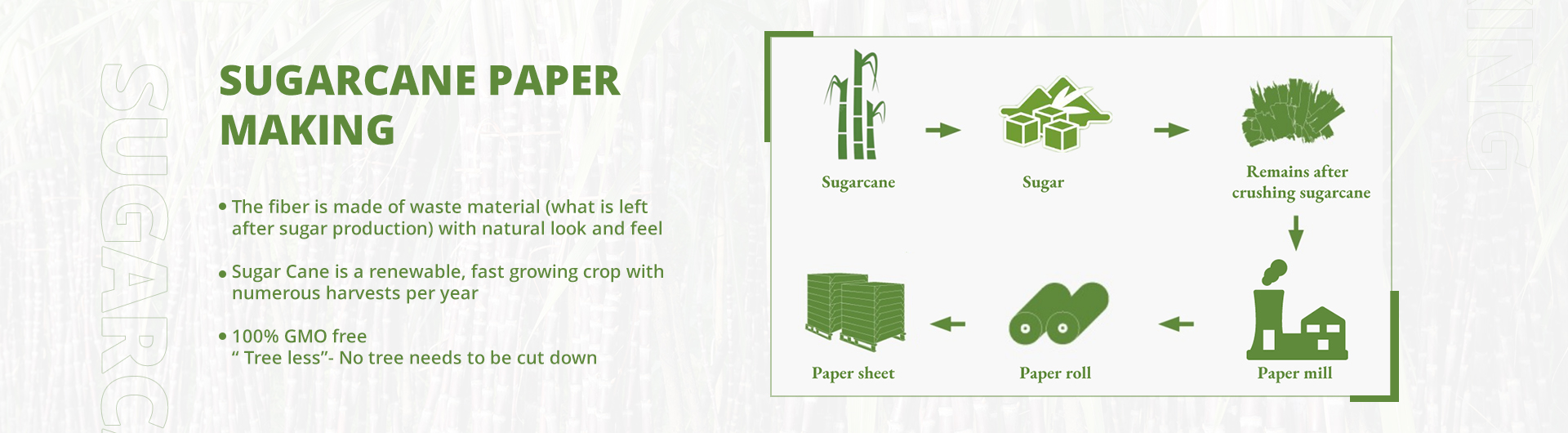

However, we have a more environmentally friendly alternative, and that is the use of bagasse to make paper and cardboard. Bagasse is a by-product of sugar cane processing, and using bagasse as a raw material can be an effective use of agricultural waste resources. PE Coated Paper Bowl Fan, Ecological Package , Sustainable Bamboo Packaging , Eco Friendly Carton ,Sustainable Cosmetic Containers . protect environment: Direct burning of sugarcane bagasse not only has low thermal efficiency, but also produces a large amount of waste gas and ash, causing pollution to air quality and the environment. In contrast, sugarcane bagasse papermaking can reduce pollutant emissions and reduce negative impacts on the environment. In addition, by converting remaining organic matter into biomass energy, it can also reduce the emission of organic waste and play a positive role in promoting environmental protection. The product will supply to all over the world, such as Europe, America, Australia,Philippines, Portland,Southampton, Frankfurt.to the use. Two types of paper cups for different uses and processing forms, the quality of the paper cup material requirements are different. Paper cup material in addition to meet the requirements of its packaging and processing performance, but also must have a certain degree of suitability for printing drama, and paper cup printing to meet the paper cup processing and molding of heat sealing conditions1. Hot drink cups.Usually used to hold hot drinks packaging trade, the material used for its processing is the use of PE single-sided composite paper, that is, single-sided laminated paper. Printing is generally done on the non-PE side. Directly printed drama on the paper surface. By the need for dry and hot drinks, the move paper cups need to be processed with a certain degree of thermal insulation, so usually these products require a certain thickness and stiffness of the paper to increase the thermal insulation of the paper cups of the publication of the printing, the larger the volume of the use of paper the thicker.

Related Products