How To Make Paper From Sugarcane Bagasse - Manufacturers, Factory, Suppliers from China

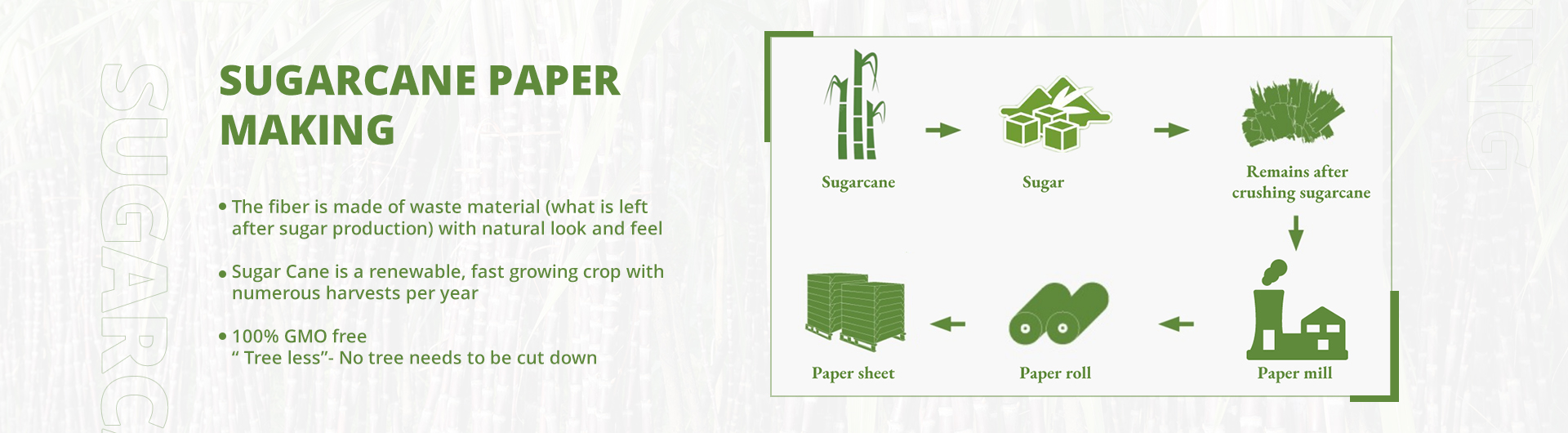

Whether you are a food packer or other business, if you have a need for sugarcane pulp paper and related products, we are able to provide you with satisfactory solutions. Please feel free to contact us, we are looking forward to cooperating with you and developing together. How To Make Paper From Sugarcane Bagasse, Compostable Packaging Food , Single Side Coated Paper , Hot Food Packaging Containers ,Food Container Box . As consumers, we also play an important role. We can support biodegradable, eco-friendly packaging by choosing products that are packaged in an environmentally responsible way. For example, when purchasing goods, we can choose products that use biodegradable packaging materials. We should also properly dispose of used packaging by placing it in an appropriate waste disposal system and ensuring that it is properly recycled and disposed of. In this way, each of us can contribute to environmental protection. The product will supply to all over the world, such as Europe, America, Australia,Kuwait, El Salvador,Thailand, British.Recyclable, sustainable plastic packaging materials is the packaging industry development trend.Our planet needs sustainable packaging solutionsGlobally, it is estimated that 42% of plastic is used for packaging, most of which is for single-use only, so the problems caused by plastic pollution in the ecosystem are long-lasting and persistent.The recycling rate for plastics is only 10%, which means that 90% of plastics are incinerated, landfilled or simply discarded into the natural environment. Plastics typically take 20 to 400 years, or more, to decompose. Decomposing plastic creates fragments or microplastics that remain in the atmospheric cycle, from water to food and soil, and in every aspect of our lives. And using sustainable materials for packaging can break this negative cycle.More and more countries are adopting single-use plastic packaging reduction mandates.In 2021, Australia announced its National Plastics Plan, which aims to ban single-use plastics by 2025. In addition to Australia, a growing number of countries and cities around the world are taking action to ban single-use plastics. In the European Union, the 2019 Single-Use Plastics Directive aims to combat the 10 most common single-use plastic items on European beaches, which account for 70 percent of all marine litter in the EU. In the United States, states such as California, Hawaii and New York have begun to legislate against single-use plastics such as plastic bags, forks and food containers. In Asia, countries such as Indonesia and Thailand have led the call for measures to ban single-use plastics.In contrast to the pressure of waiting for legislation from governments, Morgan Stanley research reports that the number of companies in the United States implementing a plastics strategy more than doubled from 2018 to 2019 alone. This suggests that, going forward, companies are willing to pay a relative profit to make a difference to environmental strategies and social responsibility goals, although this does not rule out the possibility that commercial benefits could be a major factor in the drive for sustainable packaging.Branded companies are increasingly focusing on the sustainability of their business models.Environment, Society and Governance, often referred to as ESG strategies, are being cited as a key part of many companies' growth because of the growing eco-consciousness of consumers and investors. By improving the resource efficiency of their organization, companies can improve their scores and potentially gain more business value, including improved brand reputation, customer and employee loyalty, and access to capital.The growing need for environmental action and the need for companies to achieve a win-win situation in terms of both economic profitability and sustainable development goals, it is safe to say that the development of greener, recyclable and sustainable plastic packaging materials will be a major trend in the development of the packaging industry in the near future. And the use of bagasse caused by paper and cardboard is very consistent with this environmental trend, because in the process of raw paper, do not add wood pulp, which means that sugarcane pulp paper does not need to cut down any tree, which is very environmentally friendly.

Related Products