Eco Friendly Ice Cream Packaging - China Manufacturers, Factory, Suppliers

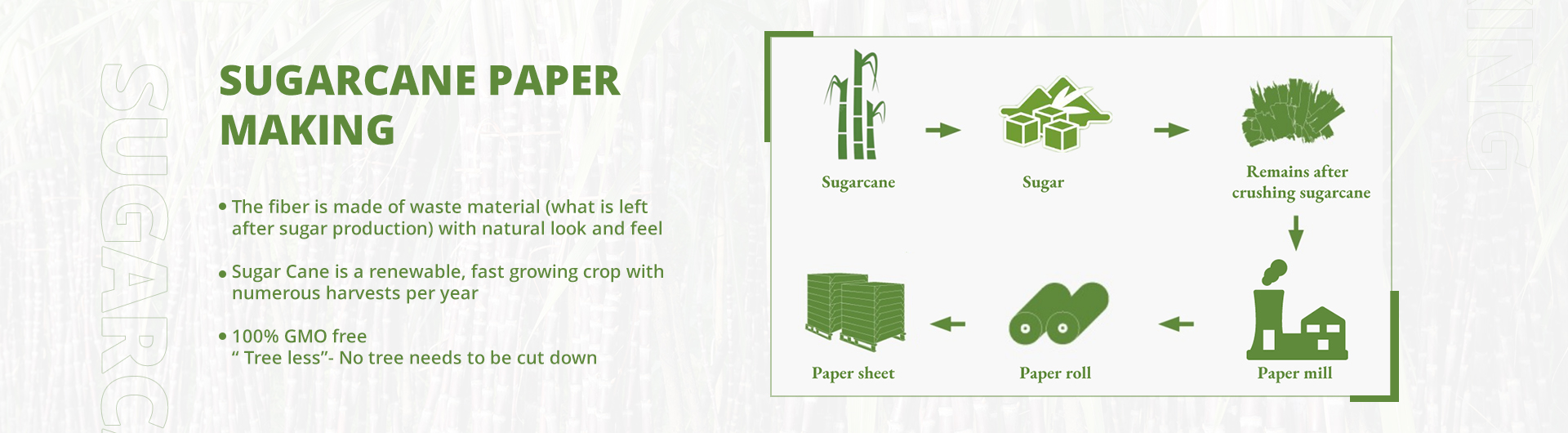

Overall, using paper made from bagasse is a sustainable solution that not only reduces dependence on forests, but also offers a wide range of uses. By choosing to use sugarcane paper, companies can realize economic benefits while protecting the environment. Against the current backdrop of increasing calls for environmental protection around the world, adopting this sustainable paper manufacturing solution will be one of the key strategies for sustainable business development. Eco Friendly Ice Cream Packaging, Eco Shipping Materials , Biodegradable Sandwich Packaging , Eco Packaging Materials ,Compostable Paper . Low-carbon environmental protection has never been something out of reach. Even the small actions of each person can have a powerful impact that cannot be underestimated. However, many times we lack the opportunity to take action. So, on this special day, Earth Day, let us have the courage to show our environmental power. By changing our lifestyles, choosing environmentally friendly products and services, and actively participating in various environmentally friendly activities, we can make a positive contribution to the future of our planet. Let us work together to protect this stage and leave a better world to the next generation. The product will supply to all over the world, such as Europe, America, Australia,Ghana, Albania,Mongolia, Morocco.From the based paper to the packaging of paper cups, mainly through the following processes: 1, PE film: that is, the based paper (white paper) with a film machine with PE film, film one side of the paper is called single-sided PE film paper: both sides of the film is called double-sided PE film paper.2、Slitting:Use the slitting machine to slit the coated paper into rectangular pieces (for the wall of the cup) and (for the bottom of the cup) rolls of simple paper.3, printing: letterpress printing machine in the rectangular sheet of paper with a variety of designs4, die-cutting: with a flat creasing and cutting machine (commonly known as die-cutting machine) will be printed on the graphics of the paper into a fan-shaped piece of paper cups used for cutting5, molding: only need the operator will fan-shaped paper cups and cup bottom rolls of paper to the paper cup molding machine feeding mouth, paper cup molding machine automatic paper feeding, sealing, punching the bottom of the operation can be automatically molded into a variety of sizes you need.The paper cup molding machine automatically feeds the paper, seals the paper, punches the bottom and so on, and then automatically molds the paper cups of various specifications you need. The whole process can be easily operated by one person.6、Packaging:the good paper cups sealed in plastic bags, and then packaged into cartons.

Related Products